'Blown Away' - Wearable Fan

Sustainable Design for Manufacture

Brief

Designers in pursuit of environmental sustainability require not only a concern for the future of our planet and the relevant tools to design more sustainable solutions, but also a strong competence in designing for manufacture.

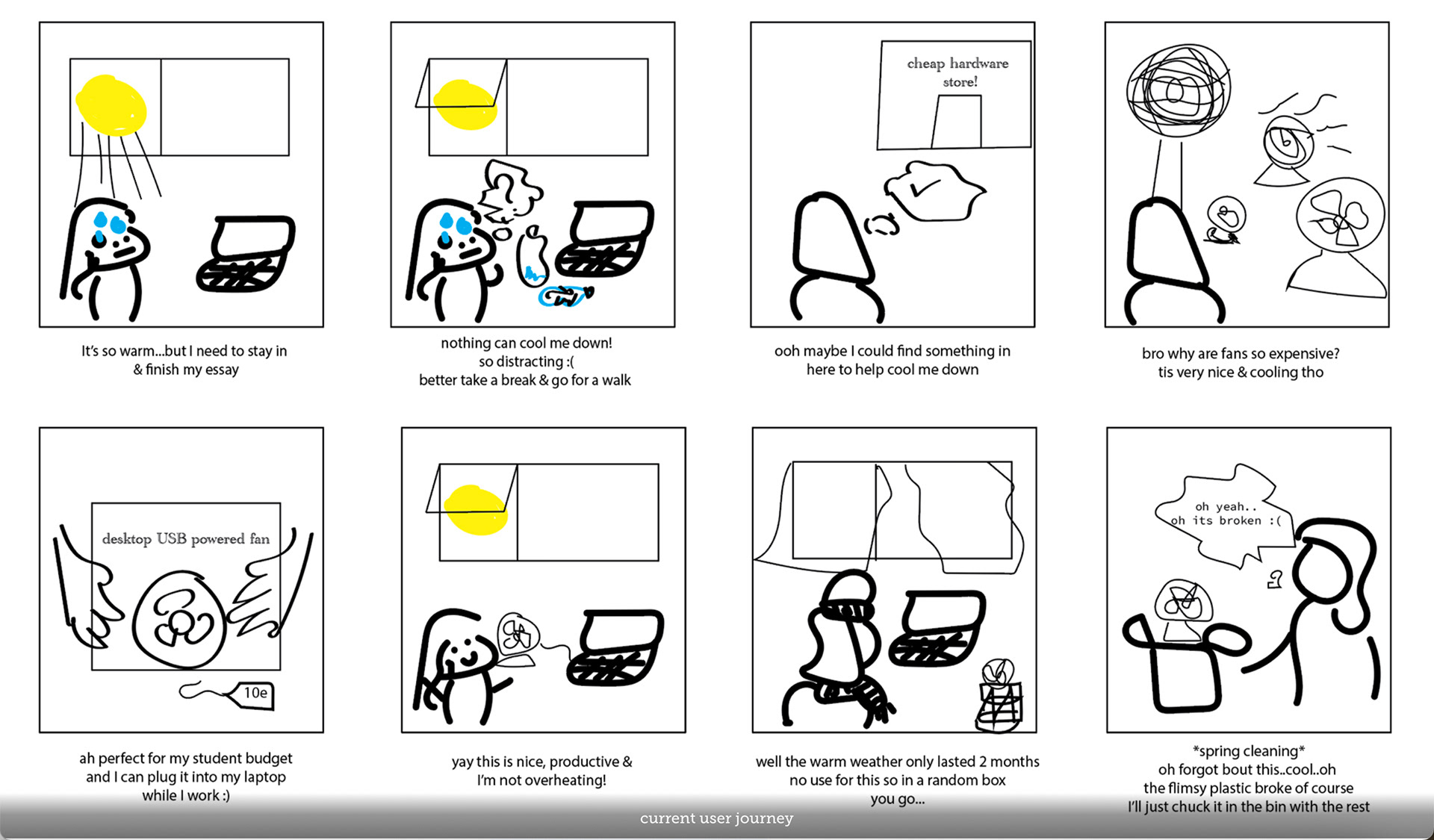

This project was about sustainability and how to pursue it, on the one hand, and about the detailed decisions to be made when designing for manufacture, on the other. Our task was to re-design a simple consumer product, (In this case I chose a desk top fan) in full detail, for a reduced environmental impact.

Research & Findings

Through conducting a life cycle analysis on the fan I found that its production and transport had the biggest environmental impact. This product consisted of 26 pieces and 5 different materials:

polypropylene, stainless steel, PVC (wire casing), copper (wire) & EVA (foam). Overall, plastic makes up 75% of total pieces & 23% of total weight of the product.

The fan contained metal parts from Japan, which then flew 3047km to China for the whole fan to be manufactured before being shipped 7775km to the distribution centre in the UK and eventually transported 500km to Ireland to be sold through hardware shops.

After interviewing users, I found that a fan of this type is only used for 3% of the year (on average).

Therefore I wanted to explore: How Might We encourage long term use of a sustainably produced fan.

Development

After numerous sketches experimenting with a variety of forms and making a moodboard of existing wearable devices, I made some sketch models for size and form which helped inform my digital sketches and models.

Outcome

Prepare to be 'Blown Away' !

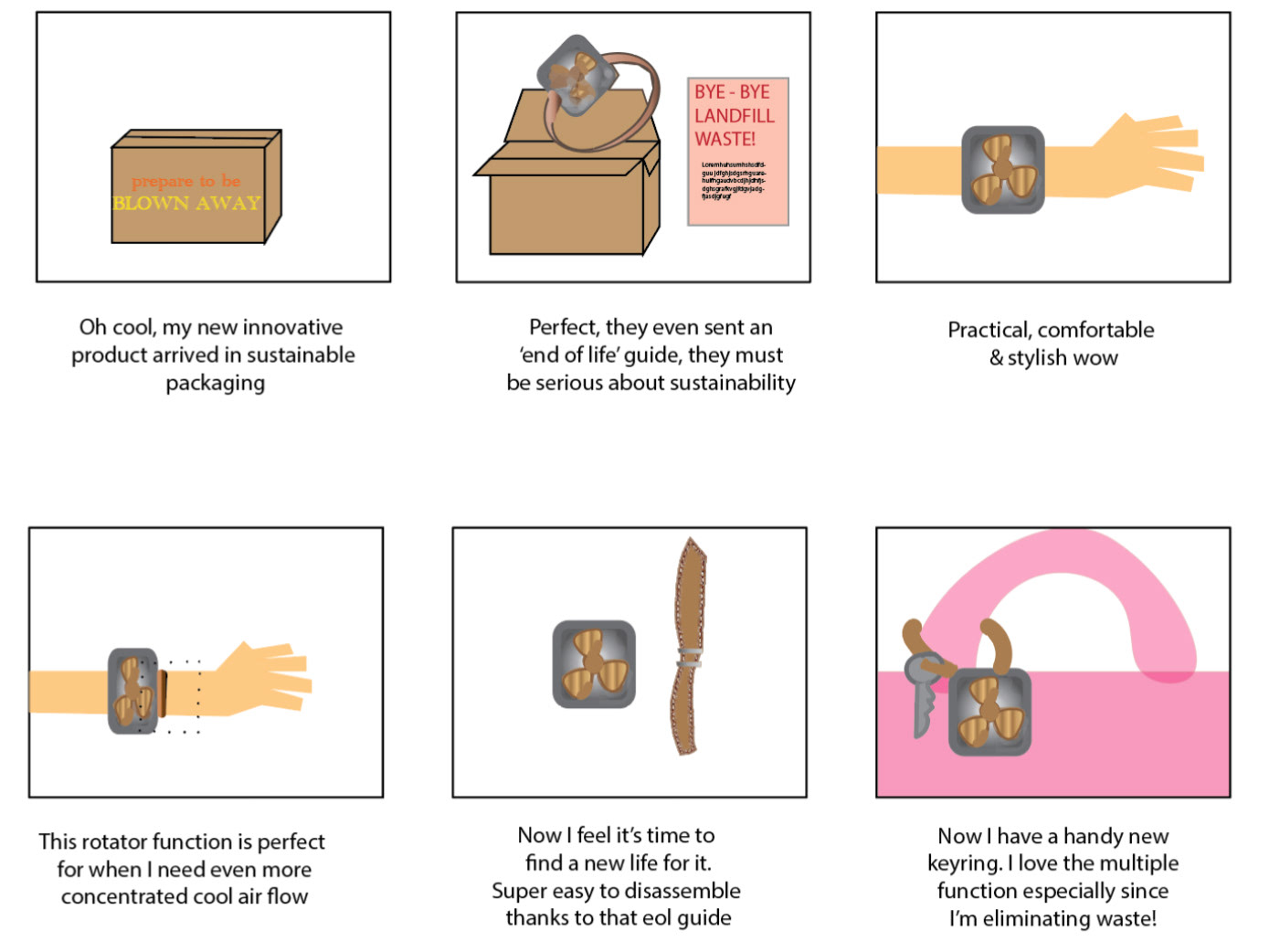

I invented a fan in wearable form in order to encourage more everyday, all year round use. It is easily portable and its clip in function allows it to rotate easily so angles can be adjusted at the users convenience while worn on its accompanying wrist strap. The body, clips and buckles are made of recycled aluminium (which can be recycled infinitely while maintaining its properties), the fan blades are made of bamboo (biodegradable), the wrist strap is made of vegan cactus leather (biodegradable) and is powered by a small solar battery.

Details

While this was my first project focusing on developing my digital fabrication skills, I produced a general assembly (GA) drawing which aids my 3D sketch allowing to direct focus to some manufacturing details. You can also see an expanded view illustration below.

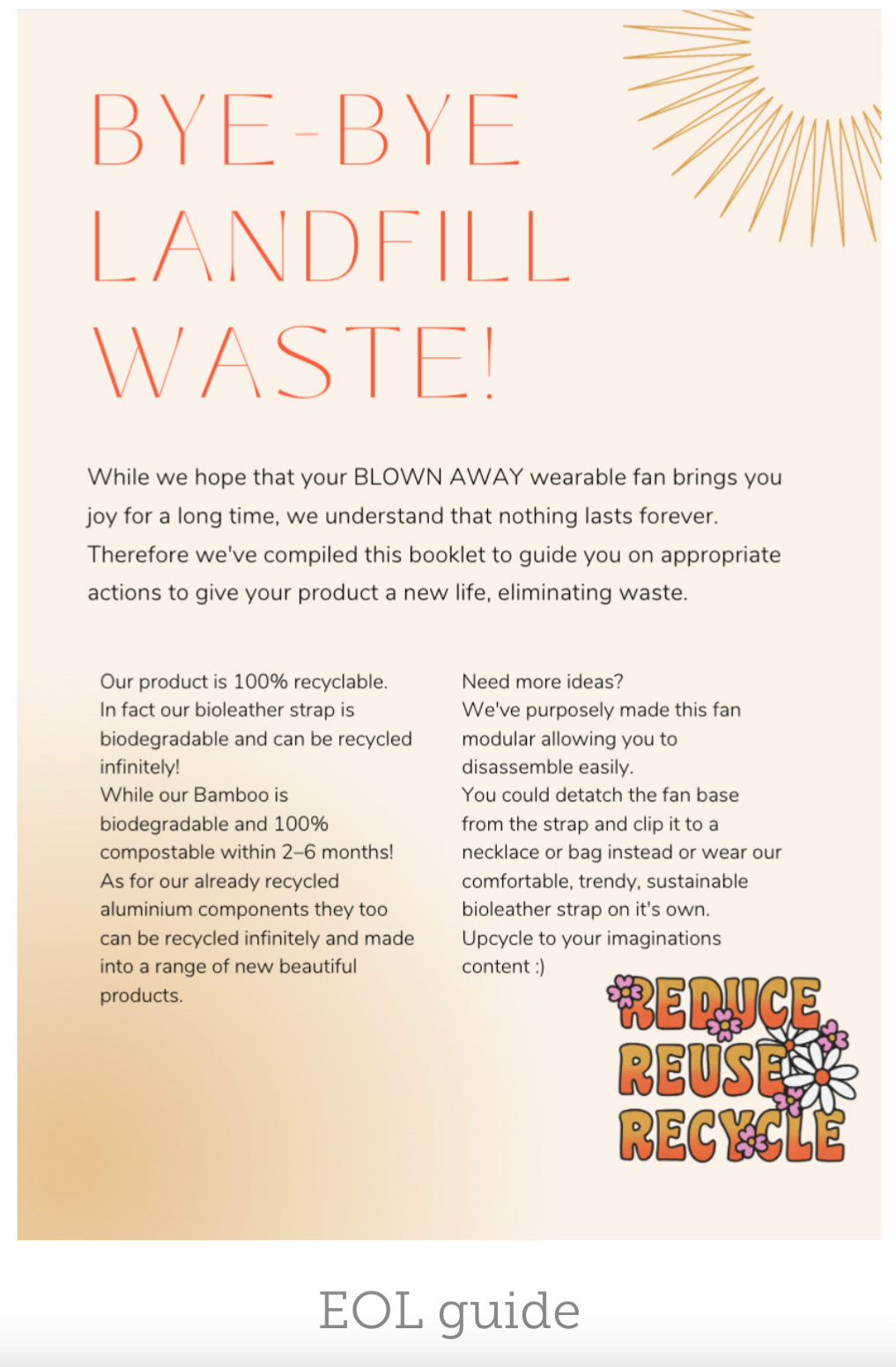

With my product I decided to provide users with an 'End of Life' (EOL) guide giving information on the materials used and how they can be disposed of properly or ,even better, upcycled into new repurposed objects given the modular wearable fans ability to be disassembled easily.